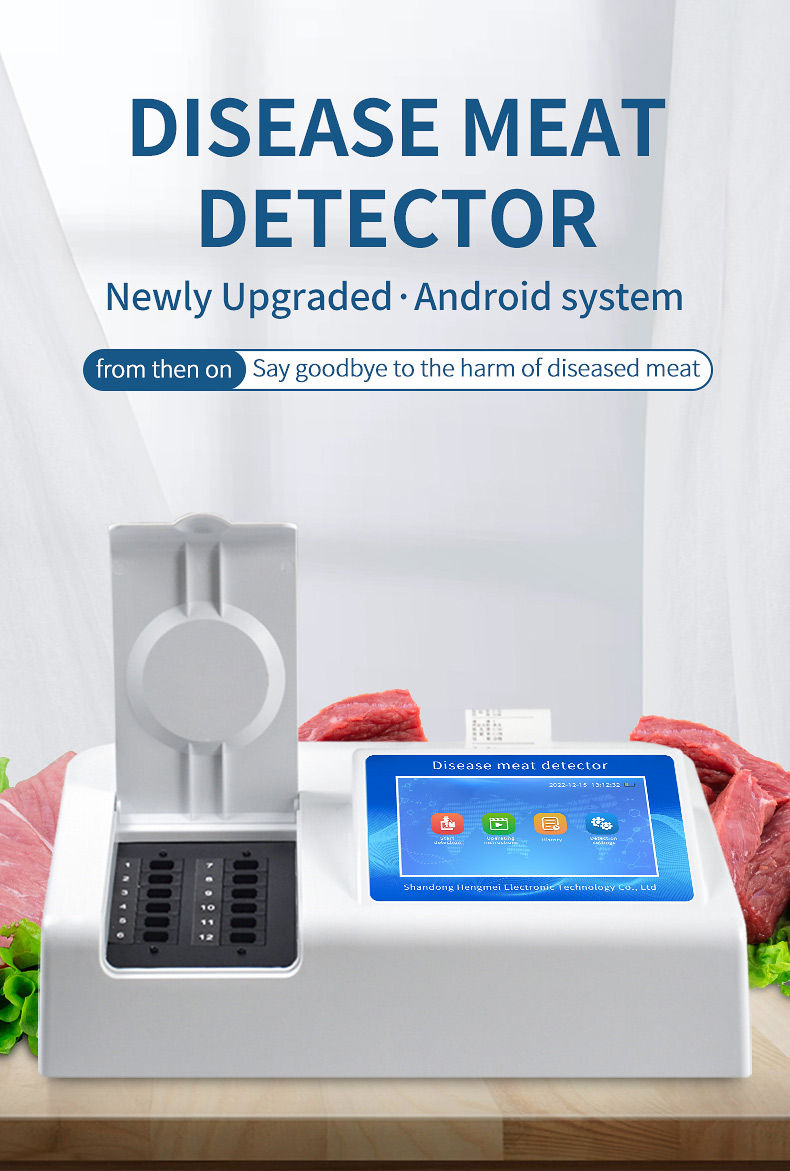

Product usage:

The disease meat tester is an integrated food safety rapid detection and analysis equipment, widely used in market supervision bureaus, food and meat product deep processing enterprises, school canteens, health departments, animal husbandry departments, slaughterhouses, inspection and quarantine departments and other units.

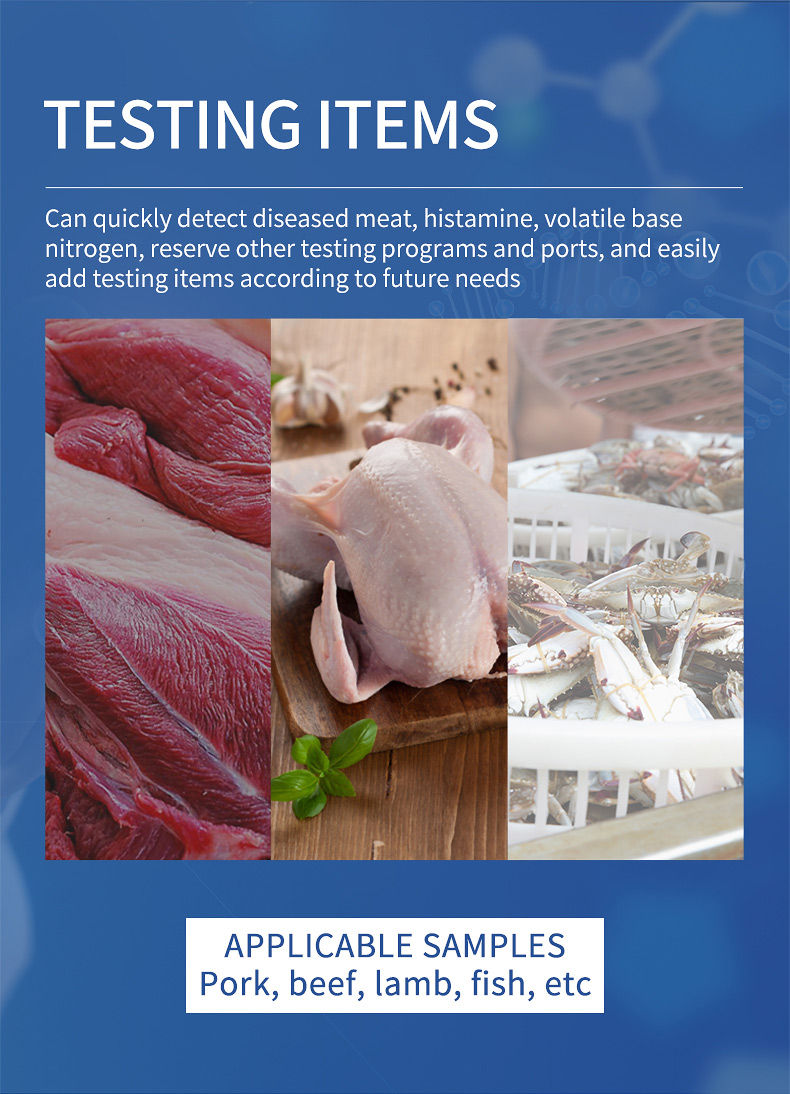

Testing items:

It can quickly detect diseased meat, histamine, and volatile base nitrogen. The instrument reserves other detection programs and ports, and can easily add detection items according to future needs.

[Applicable Samples]

Pork, beef, lamb, fish, etc

Function introduction:

1. The Android intelligent operating system adopts more efficient and user-friendly operation. The instrument has Ethernet connection, WiFi network upload, GPRS wireless remote transmission function, and can quickly upload data.

2. High degree of intelligence, the instrument has self checking function: it has power on self checking and zero adjustment functions, and automatic detection of repeatability function.

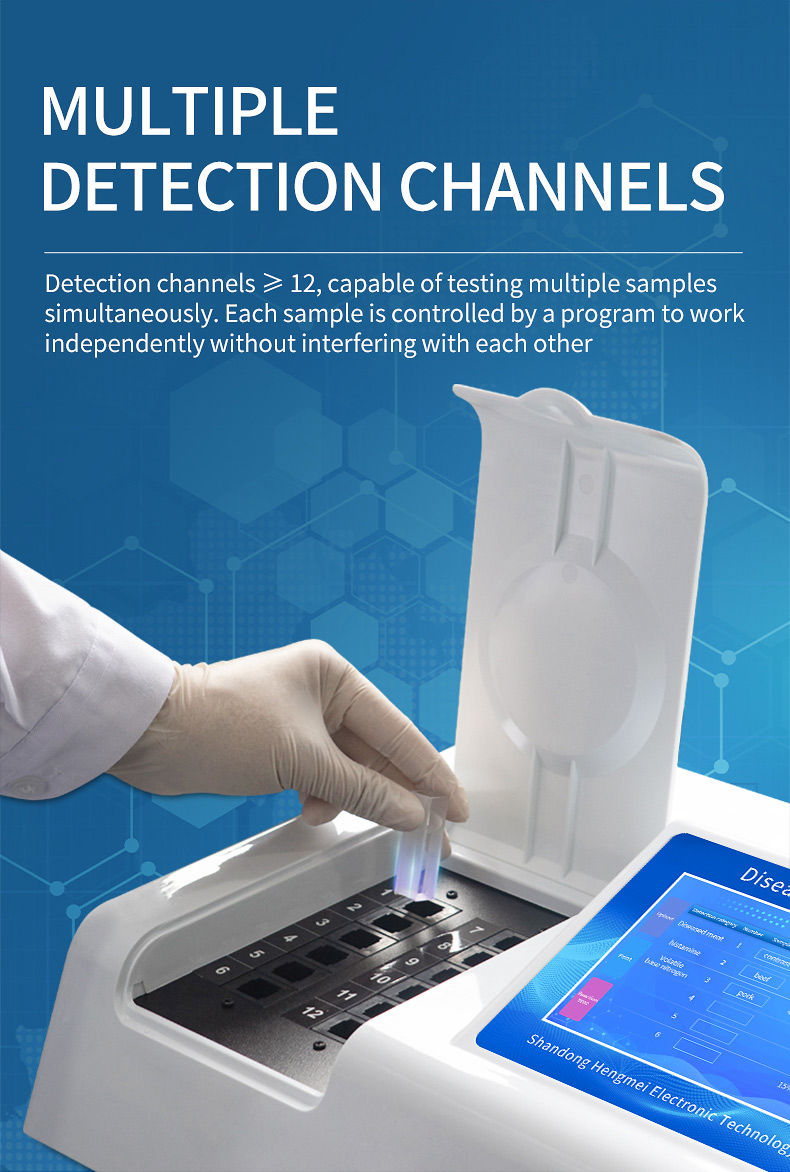

3. Detection channels: ≥ 12 detection channels, capable of testing multiple samples simultaneously. Each sample is controlled by a program to work independently without interfering with each other.

4. Display mode: ≥ 8-inch LCD touch screen display, user-friendly Chinese operation interface, intuitive and simple reading.

5. Equipped with a new generation embedded thermal printer, it can choose between manual printing or automatic printing. After the inspection is completed, the inspection report and QR code can be automatically printed.

6. The light source adopts imported ultra high brightness light-emitting diodes, which have high precision, strong stability, controllable light source, can turn off unused light sources, and lower power consumption.

7. Designed with USB 2.0 interface, it is convenient for data storage and movement, and can be directly connected to a computer at any time. The instrument can also be controlled by a computer. Implement data query, browsing, analysis, statistics, printing, etc.

8. The instrument is equipped with a regulatory platform. The data can be uploaded via LAN and Internet, and the test results can be directly transmitted to the food safety supervision platform. Conduct regional food safety supervision and big data analysis processing, detect the long-term and short-term dynamics of regional food safety, and achieve food safety problem estimation and early warning

9. The instrument has a multi category sample menu library, which allows for flexible selection of detection samples. Different detection channels can simultaneously detect different sample items.

10. Sample processing is simple and labor-saving, and the overall operation is fast, safe, and convenient.

11. The instrument has its own protection function, which can set a username and password to prevent non staff operations.

12. High sensitivity, high detection accuracy, high repeatability accuracy, scanning high-precision optical sensor.

13. Built in powerful database allows for direct selection of sample names, detection indicators, and inspection units on the instrument, as well as direct editing and input of sample names, detection indicators, inspection units, and other information into the sample database.

14. The instrument has the functions of recalibration, locking, and factory reset.

15. Supports USB storage. The result judgment line can be modified, the reference value calibration value can be saved, and data will not be lost when power is turned off.

Main parameters:

1. The main control chip adopts ARM Cortex-A7, RK3288/4-core processor, with a main frequency of 1.88GHz, faster operation speed and stronger stability.

2. DC 12V power supply, can be connected to car power supply, can be equipped with 6ah large capacity rechargeable lithium battery, convenient for outdoor mobile testing.

3. Dual wavelength cold light source, each channel is equipped with 405nm and 520nm wavelength light sources, and comes standard with advanced optical path switching devices. The patented optical path switching function can achieve up to 64 wavelengths, and all detection items can be detected simultaneously in all channels.

4. Automatic adjustment and calibration of light source brightness

5. Intelligent constant current and voltage regulation, automatic calibration of light intensity, and long-term continuous operation of the light source without temperature drift phenomenon.

6. Continuous injection and testing

7. Sample numbers are automatically accumulated.

8. The testing items can be expanded.

9. The test results can be printed and uploaded in batches.

10. The test results are in an Excel spreadsheet, which can be copied by connecting to a computer.

11. Storage capacity for 200000 test results

12. Standard USB interface, no driver installation required.

13. Configurable large capacity lithium battery, firmware upgradable

Technical parameters:

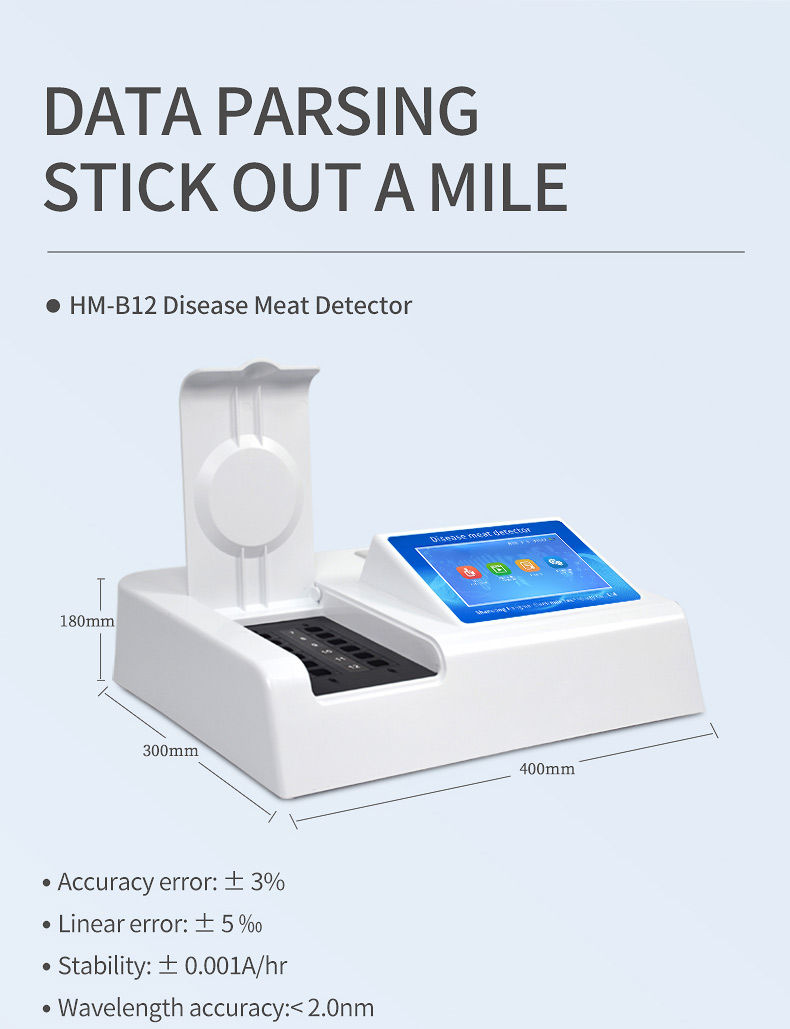

☆ Accuracy error: ± 3%

☆ Linear error: ± 5 ‰

Stability: ± 0.001A/hr

☆ Wavelength accuracy:<2.0nm

☆ Wavelength range: 450nm

☆ Wavelength range: 410nm

☆ Wavelength range: 480nm

☆ Freshness: detection limit 20mg/kg linear range 0-1000mg/kg

☆ Histamine: Detection limit: 50mg/kg Linear range: 50-2000mg/kg

☆ Volatile base nitrogen: Detection limit: 10mg/kg Linear range: 0-300mg/kg

☆ Transmission specific gravity repeatability: ± 1%

☆ Data storage of 80000 records

☆ Colorimetric dish: 10 × 10mm standard sample cell

☆ Appearance size: 400x300X180 (mm)

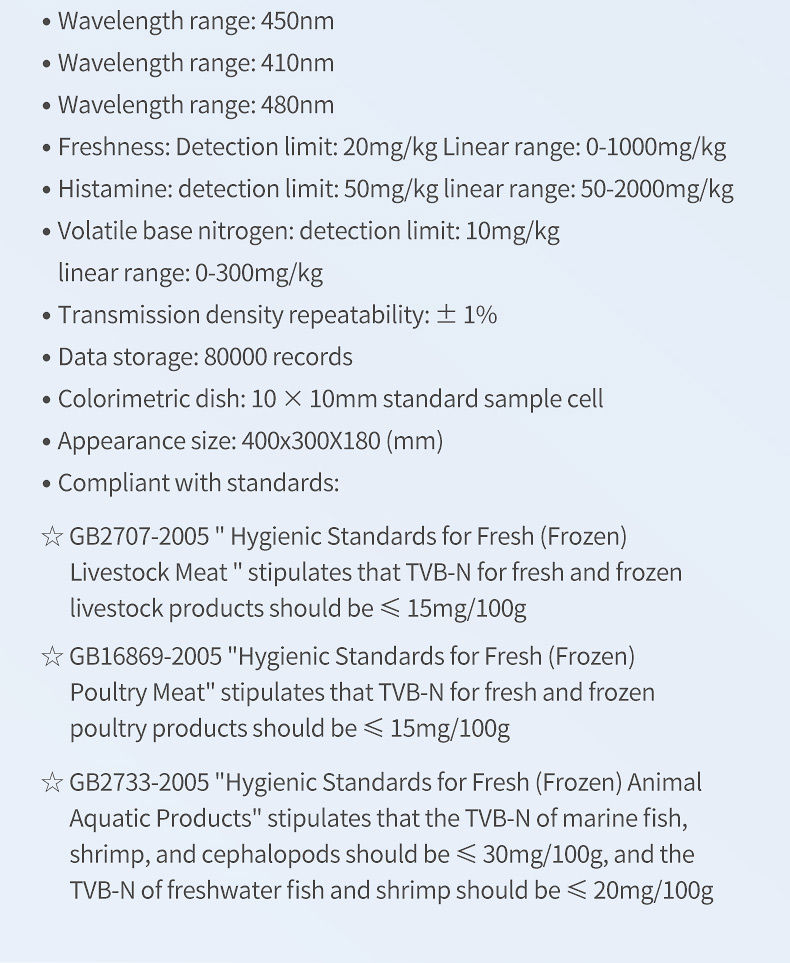

【 Compliant with standards 】

GB2707-2005 "Hygienic Standards for Fresh (Frozen) Livestock Meat" stipulates that TVB-N for fresh and frozen livestock products should be ≤ 15mg/100g,

GB16869-2005 "Hygienic Standards for Fresh (Frozen) Poultry Meat" stipulates that TVB-N for fresh and frozen poultry products should be ≤ 15mg/100g,

GB2733-2005 "Hygienic Standards for Fresh (Frozen) Animal Aquatic Products" stipulates that the TVB-N of marine fish, shrimp, and cephalopods should be ≤ 30mg/100g, and the TVB-N of freshwater fish and shrimp should be ≤ 20mg/100g

Article address:http://www.hmfoodtesting.com/rzp2/72.html

Current

location:

Current

location:

+86

17853698681

+86

17853698681