Product Introduction

The QC4 four integrated pretreatment machine is an integrated system that combines drying, centrifugation, homogenization, and mixing functions, greatly simplifying and centralizing the general operation process of sample pre-treatment. Combined with a mobile and portable engineering plastic box, it is particularly suitable for rapid on-site quality and safety testing of agricultural and veterinary drug residues, livestock, poultry, and aquatic products.

Built in integrated instrument configuration table

Number Function Name Specification Function Description Quantity

1. Air drying function 12. Heating incubation and drying 1

2 centrifugal function 20mL × 6 high-speed centrifugal stratification 1

3 Homogenization and Crushing Function 300mL Tissue Homogenization and Crushing 1

4 oscillation mixing function 20mL mixing, oscillation 1

Product Features

1. Compact in function, integrating four commonly used sample pre-processing functions to complete one-stop sample processing.

2. The structure is stable, and the chassis is made of high-quality engineering plastic, which has excellent impact resistance, corrosion resistance, and portability.

3. Stable operation, the machine adopts a five inch full-color LCD screen with strong functional indication. All user operations are physical switches to prevent operation failure when wearing gloves and liquid splashing.

Technical Parameters

Instrument size: 520 × 415 × 225mm

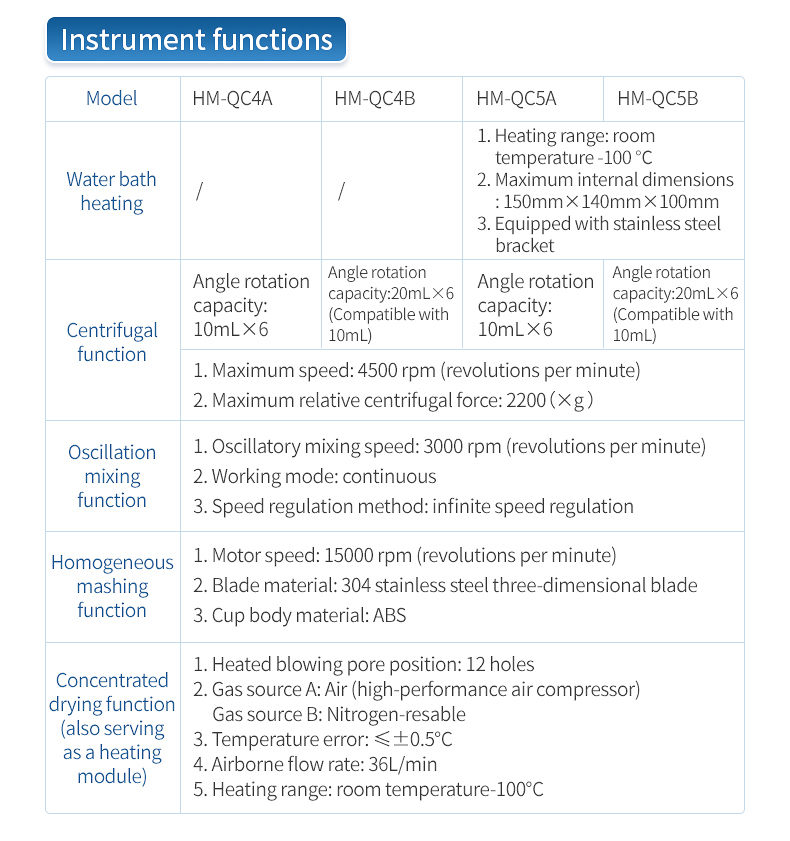

Centrifugal function

1. Maximum speed: 4500 rpm (revolutions per minute)

2. Maximum relative centrifugal force: 2200 (× g)

3. Angular conversion capacity: 20mLx6 (compatible with 10mL)

4. Centrifuge time: 1-999min

5. Noise: ≤ 55dB

Oscillatory mixing function

1. Oscillatory mixing speed: 3000 rpm (revolutions per minute)

2. Working mode: continuous

3. Speed regulation method: infinite speed regulation

4. Mixing volume: 1-50mL

Homogeneous crushing function

1. Motor speed: 15000 rpm (revolutions per minute)

2. Blade material: 304 stainless steel three-dimensional blade

3. Cup body material: ABS

4. Continuous working time: ≤ 40 seconds

5. Interval time: ≥ 2 minutes

Concentrated drying function (also serving as a heating module)

1. Heating and blowing holes: 12 holes

2. Air source A: Air (high-performance air compressor)

Gas source B: Can be connected to nitrogen gas

3. Temperature error: ≤± 0.5 ℃

4. Carrier gas flow rate: 36L/min

5. Heating range: room temperature -100 ℃

6. Display accuracy: ± 0.1 ℃

7. Lifting method: manual

5、 Shipping accessories

Number, Name, Quantity

1 host, 1 unit

6 20mL centrifuge tubes

3 three plug power cords, 1 piece

4 manuals, 1 copy

5 certificates of conformity, 1 copy

6 packing lists, 1 copy

7 instrument boxes, 1 piece

Article address:http://www.hmfoodtesting.com/qcl1/147.html

Current

location:

Current

location:

+86

17853698681

+86

17853698681